Protecting Your Valuable Metals: The Power of GreenVCI Shrink Film in Corrosion Prevention

In the world of metal manufacturing and logistics, corrosion is the silent enemy that can turn high-quality products into costly scrap overnight. If you’ve been following our series on the various types of corrosion, you know just how diverse and damaging these issues can be. We’ve covered them all in our previous posts. But knowing the problems is only half the battle; the real win comes from smart, practical solutions. That’s where GreenVCI Shrink Film steps in as a reliable choice for anyone handling metal storage, shipping, or long-term preservation.

What Makes GreenVCI Shrink Film Stand Out in VCI Technology?

At its heart, GreenVCI Shrink Film is a specialized VCI shrink film built to shield metals from rust and degradation without the mess of older methods. VCI stands for Vapor Corrosion Inhibitor: it releases invisible vapors that settle on metal surfaces, forming a thin molecular shield against moisture, oxygen, and corrosive agents. Unlike oily coatings or desiccants that demand extra cleanup, this shrink film keeps things clean and dry, ready to use the moment you unpack them.

What really sets GreenVCI apart is its smart dual-protection approach. It combines a strong physical barrier that blocks out humidity, salt, pollutants, and other threats with built-in chemical VCI action that fights corrosion right at the source. This combo proves especially strong against the full range of corrosion types we’ve explored, whether it’s preventing pitting in salty environments or stopping galvanic reactions between mixed metals.

Key Benefits of Using GreenVCI Shrink Film for Your Operations

Let’s look at why industries keep choosing VCI shrink films like GreenVCI for their day to day corrosion control. These features come straight from how the product performs in real settings:

- Dual Protection for Maximum Defense: The physical layer seals tightly while the chemical VCI vapors work inside, creating layered defense. This tackles everything from fretting corrosion during bumpy transport to fatigue corrosion under ongoing stress; a common challenges from our corrosion types series.

- Streamlined Logistics and Immediate Usability: No waiting around for drying or degreasing. GreenVCI lets you unpack and go straight to work or assembly. That cuts downtime and speeds up your entire supply chain.

- Customizable and Versatile for Any Metal: From steel and aluminum to copper, brass, and alloys, it handles a broad lineup. You can tailor sizes and thicknesses to match your needs, making it great for avoiding galvanic corrosion in mixed metal setups or uniform corrosion on big flat areas.

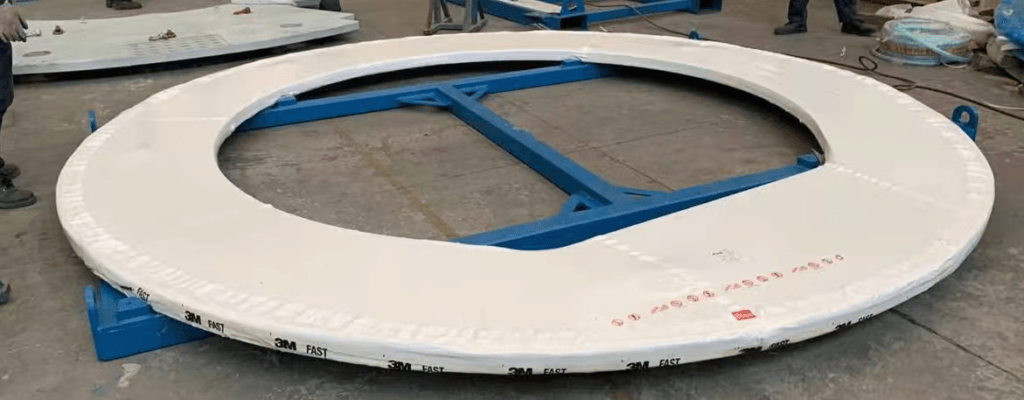

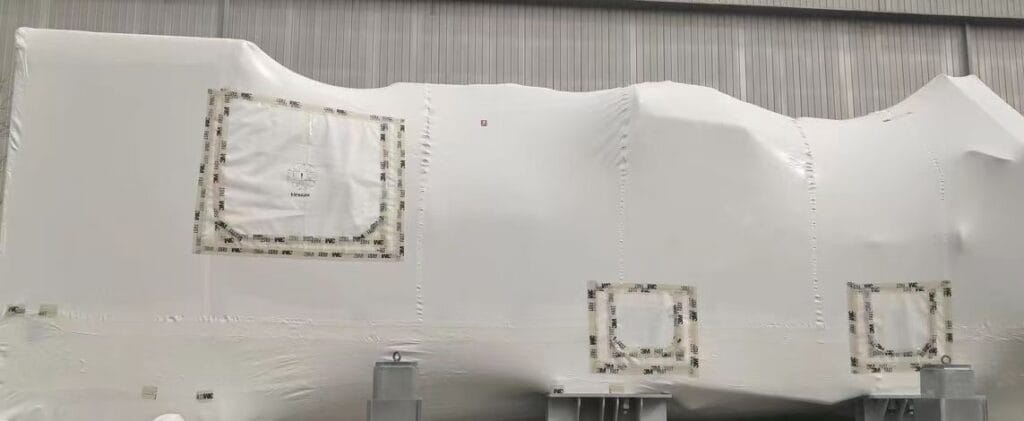

- Flexible Design for Challenging Shapes: Oversized machinery, odd shaped components, or bulky equipment? GreenVCI shrinks down with heat to hug irregular forms perfectly, sealing out contaminants in spots where crevice corrosion loves to hide or where pitting can start on uneven surfaces.

- Save Material & Labor Costs: Beyond the protection, GreenVCI delivers real savings on the bottom line. It replaces messy oils, greases, or multi-layer packaging that eat up materials and require time-intensive application. Wrapping is quick and removal is simple with no residue left behind, slashing labor hours compared to traditional rust preventives. You also avoid extra costs from corrosion damage, rework, returns, or scrapped parts. Many users see lower overall material use since one effective layer does the job of several, plus the film’s durability means less waste over time. It’s a practical way to cut expenses while keeping your metals in top shape.

Picture shipping heavy equipment across long distances without salt spray sparking erosion corrosion, or storing automotive components in a humid facility free from stress corrosion cracking worries. GreenVCI makes that happen, stretching shelf life and trimming unnecessary losses along the way.

How GreenVCI Shrink Film Fits Into Your Corrosion Prevention Strategy

Tying back to our series on the types of corrosion, GreenVCI directly counters each one. For galvanic issues, the VCI creates a balanced environment between metals; the tight shrink seal stops electrolyte moisture from collecting. Against fretting or fatigue, the tough film holds steady through movement and vibration.

Application is straightforward: wrap the item, apply heat to shrink it snug, and let the VCI do its job. It’s often recyclable too, fitting nicely with sustainability efforts. Automotive, aerospace, heavy machinery, and export operations have all cut corrosion headaches and related costs by making VCI shrink films part of their routine.

Why Choose GreenVCI Over Traditional Shrink Wrap?

Basic shrink films handle packaging, but they don’t fight corrosion actively. GreenVCI builds in long-lasting VCI protection, years in controlled conditions, without needing separate inhibitors or messy prep. The green tint helps spot protected items fast in storage, and the overall approach saves on labor, cleanup, and potential damage claims.

In short, if corrosion keeps chipping away at your margins, GreenVCI Shrink Film provides a solid, forward-thinking fix. It’s more than packaging, it’s dependable protection for your metals. Ready to strengthen your setup? Check out our full lineup of VCI solutions and find what fits your operation best.