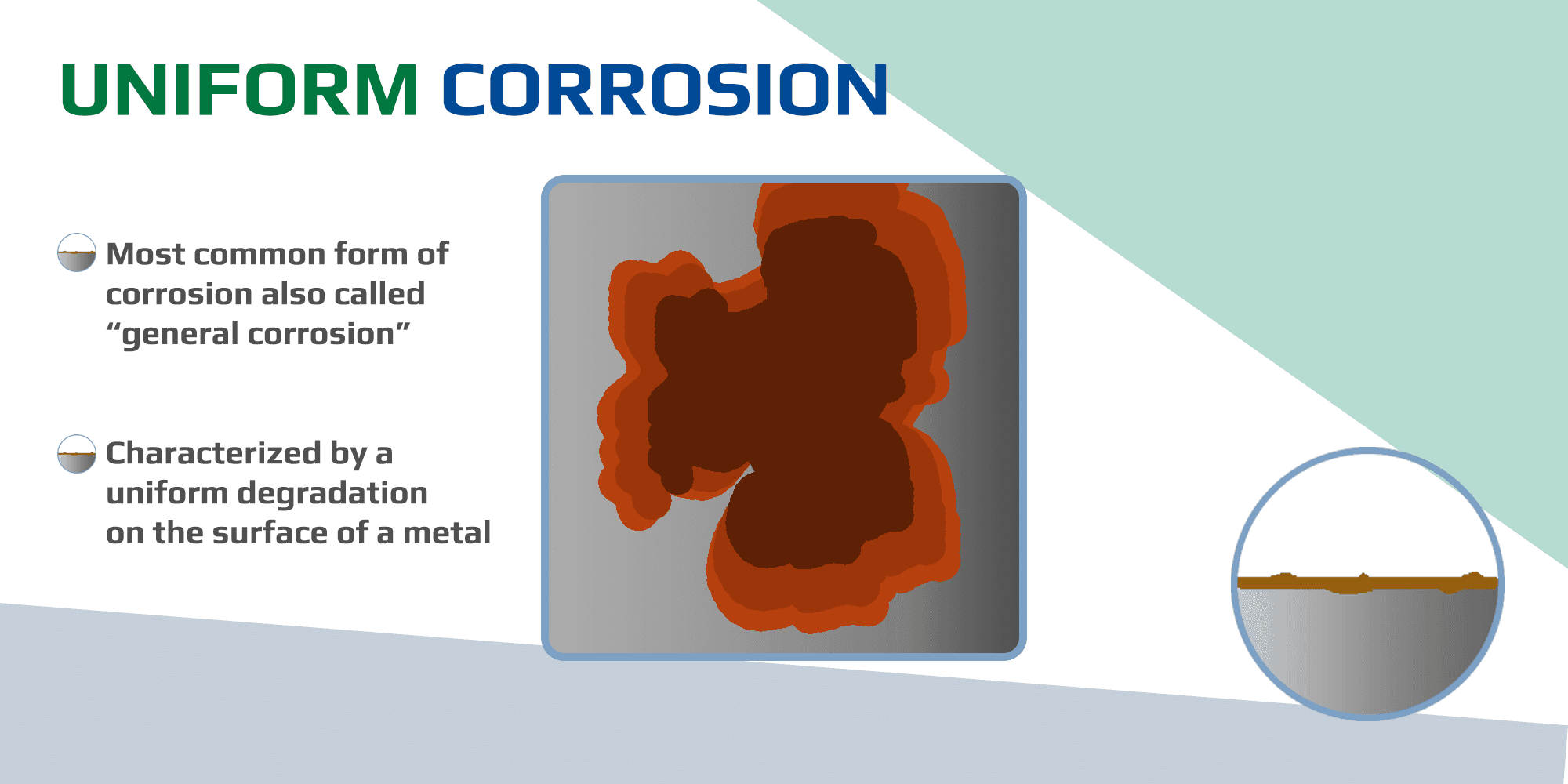

Uniform corrosion, also known as general corrosion, is the most common corrosion type, causing even material loss across metal surfaces. It’s predictable, allowing planned maintenance, but can lead to significant damage if unchecked.

What is Uniform Corrosion?

Uniform corrosion evenly attacks metal surfaces, resulting in consistent thinning. Examples include rust on iron and tarnish on silver. Its predictability makes it manageable compared to localized corrosion.

Causes of Uniform Corrosion

Key factors include:

Moisture: Water, especially with salts or acids.

Oxygen: Forms oxides with metals.

Temperature: Accelerates corrosion.

pH Levels: Acidic or alkaline environments.

Impurities: In metal or environment.

Effects of Uniform Corrosion

Reduced Strength: Thinning weakens metal.

Aesthetic Damage: Rust or corrosion mars appearance.

Increased Costs: Frequent maintenance and replacements.

Potential Failures: Risks structural issues.

Prevention with VCI Technology

Volatile Corrosion Inhibitor (VCI) technology prevents uniform corrosion effectively. GreenVCI’s VCI products release protective compounds, forming an invisible layer on metal surfaces to block corrosive elements. Benefits include:

Cost-Effective: Lowers maintenance costs.

Eco-Friendly: Biodegradable and non-toxic.

Efficient: Protects hard-to-reach areas.

Reliable: Proven in industries like automotive and aerospace.

Conclusion

Uniform corrosion poses significant challenges, impacting metal integrity and costs. By understanding its causes and effects, and using GreenVCI’s VCI technology, industries can protect assets efficiently. Explore GreenVCI’s solutions at GreenVCI to ensure rust-free metal.