Stress corrosion cracking is a stealthy and potentially catastrophic form of corrosion that strikes metals exposed to both mechanical tension and harsh chemical surroundings, often leading to brittle fractures without warning. Distinct from uniform corrosion, which erodes surfaces steadily (as covered in our guide to uniform corrosion), or crevice corrosion, which hides in tight spaces (detailed in our post on crevice corrosion), SCC targets vulnerable spots under load, turning ductile materials unexpectedly fragile. This makes it a top concern for engineers in high-stakes fields, where a single crack can spell disaster.

What is Stress Corrosion Cracking?

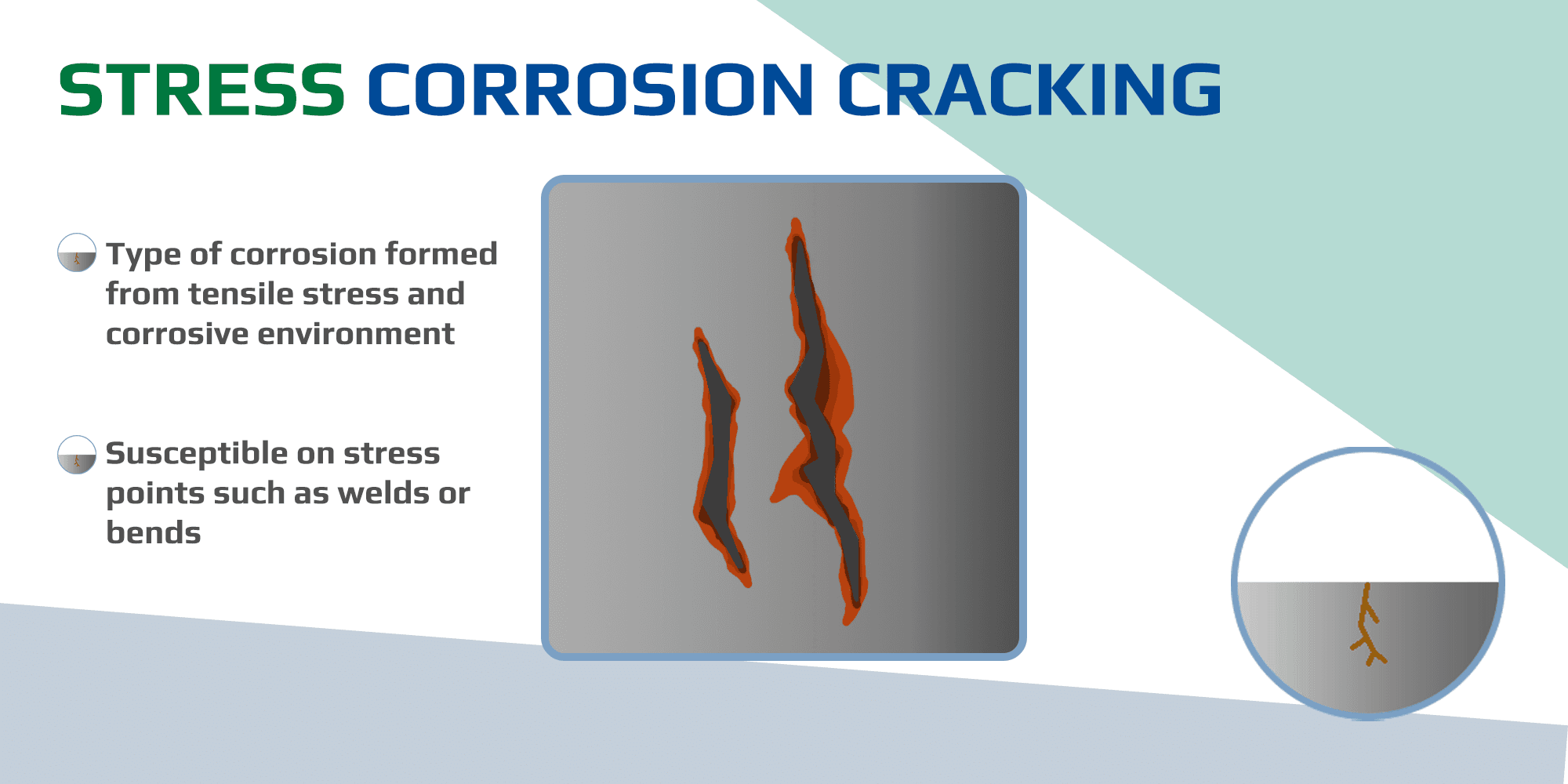

Stress corrosion cracking (SCC) refers to the progressive formation and growth of fine cracks in metal alloys when they face simultaneous tensile stresses—either from external forces or built-up residuals—and a specific corrosive medium. These cracks typically branch out in a transgranular or intergranular pattern, starting microscopically but expanding rapidly under the right conditions. It’s especially prevalent in materials like austenitic stainless steels, high-strength aluminum alloys, and certain titanium grades, where the environment might include chlorides, hydrogen sulfide, or alkaline solutions. Unlike general rusting, SCC demands this dual assault: no stress, no cracking; no corrosives, no issue. Early detection is tough because cracks often hide beneath the surface until they propagate fully.

Causes of Stress Corrosion Cracking

A perfect storm of mechanical and chemical factors ignites SCC, making prevention a matter of addressing each root:

- Tensile Stress Exposure: Residual stresses from welding, machining, or cold working, combined with applied loads, stretch metal lattices, creating pathways for crack initiation.

- Corrosive Media Specificity: Certain electrolytes—like chlorides in seawater or caustics in chemical plants—disrupt protective oxide films, allowing localized attack at stressed sites.

- Material Susceptibility: Alloys engineered for strength, such as martensitic steels or precipitation-hardened aluminums, often lack resistance to SCC in aggressive settings.

- Environmental Triggers: Elevated temperatures speed up reactions, while contaminants like sulfides amplify the corrosiveness in industrial atmospheres.

- Fabrication Oversights: Imperfect welds, sharp bends, or uneven heat treatments introduce high-stress concentrations that serve as crack starters.

Effects of Stress Corrosion Cracking

The consequences of SCC ripple far beyond the initial flaw, demanding vigilant management to avert broader fallout:

- Sudden Structural Failure: Interconnected cracks can lead to leaks or ruptures in pipelines, aircraft components, or pressure vessels, often without prior deformation warnings.

- Reduced Equipment Lifespan: What starts as minor fissures accelerates fatigue, slashing operational reliability in demanding applications.

- Operational and Safety Risks: In sectors like petrochemicals, nuclear power, or offshore platforms, unchecked SCC heightens the chance of accidents, endangering lives and the environment.

- Economic Strain: Frequent inspections, emergency fixes, and replacements drive up costs, with downtime alone costing industries millions annually.

Prevention with VCI Technology

Volatile Corrosion Inhibitor (VCI) technology stands out as a proactive defense against SCC, delivering vapor-based protection that seeps into stressed zones without invasive applications. GreenVCI’s advanced VCI formulations release protective molecules that adsorb onto metal surfaces, stabilizing oxide layers and neutralizing aggressive ions—even in the presence of tensile strains. Ideal for safeguarding welds, bends, and assemblies during storage, shipping, or idle periods, our solutions interrupt the corrosion-stress synergy at its core. Standout benefits include:

- Targeted Reach: Vapors infiltrate hard-to-access stress points, offering uniform coverage where liquid inhibitors falter.

- Sustainable Edge: Derived from plant-based, nitrite-free compounds, GreenVCI products are biodegradable and compliant with global eco-standards, minimizing your environmental footprint.

- Industry Adaptability: Proven effective in aerospace, energy, and heavy machinery, integrating seamlessly into existing workflows.

- Long-Term Savings: By curbing SCC initiation, VCI extends service intervals, cuts maintenance expenses, and boosts asset value.

Pairing VCI with design tweaks—like stress-relieving heat treatments or cathodic protection—creates a layered shield, but GreenVCI’s ease of use makes it a game-changer for everyday reliability.

Conclusion

Stress corrosion cracking embodies the treacherous interplay of force and chemistry, quietly undermining even the toughest metals until failure looms large—yet knowledge of its triggers empowers decisive action. From selecting resilient alloys to deploying cutting-edge barriers, the path to mitigation is clear. Turn to GreenVCI’s VCI innovations for a reliable, green ally in the fight against SCC, complementing defenses against crevice, pitting, and uniform corrosion alike. Explore our full lineup of corrosion inhibitors at GreenVCI today and keep your operations crack-proof.