GreenVCI delivers advanced corrosion solutions and practical guidance to help major industries improve protection, reduce costs, and operate more sustainably. Beyond product development, we provide on-site inspections, technical consulting, and tailored VCI applications to address your specific corrosion challenges with long-term reliability.

GreenVCI provides on-site inspections and expert consulting to identify corrosion risks and recommend practical solutions. Our teams diagnose issues, review your current methods, and deliver clear reports comparing GreenVCI options with existing systems.

Our R&D team develops formulations, integrates added functions such as anti-static or moisture control, and rapidly prototypes new concepts. With vertically integrated labs and manufacturing, we deliver precise, high-quality custom products efficiently.

Our in-house laboratories ensure every product meets strict performance and safety standards. After delivery, our support team assists with application guidance, troubleshooting, and continuous quality assurance to keep your operations running smoothly.

At GreenVCI, our core value is driving the future of corrosion protection through reusable, recyclable, and biodegradable technologies. We are committed to setting a new global standard for truly “green” VCI formulations that are free from harmful nitrites, secondary amines, and environmentally persistent chemicals. Our approach combines sustainability with high performance, ensuring that corrosion protection can be both effective and responsible.

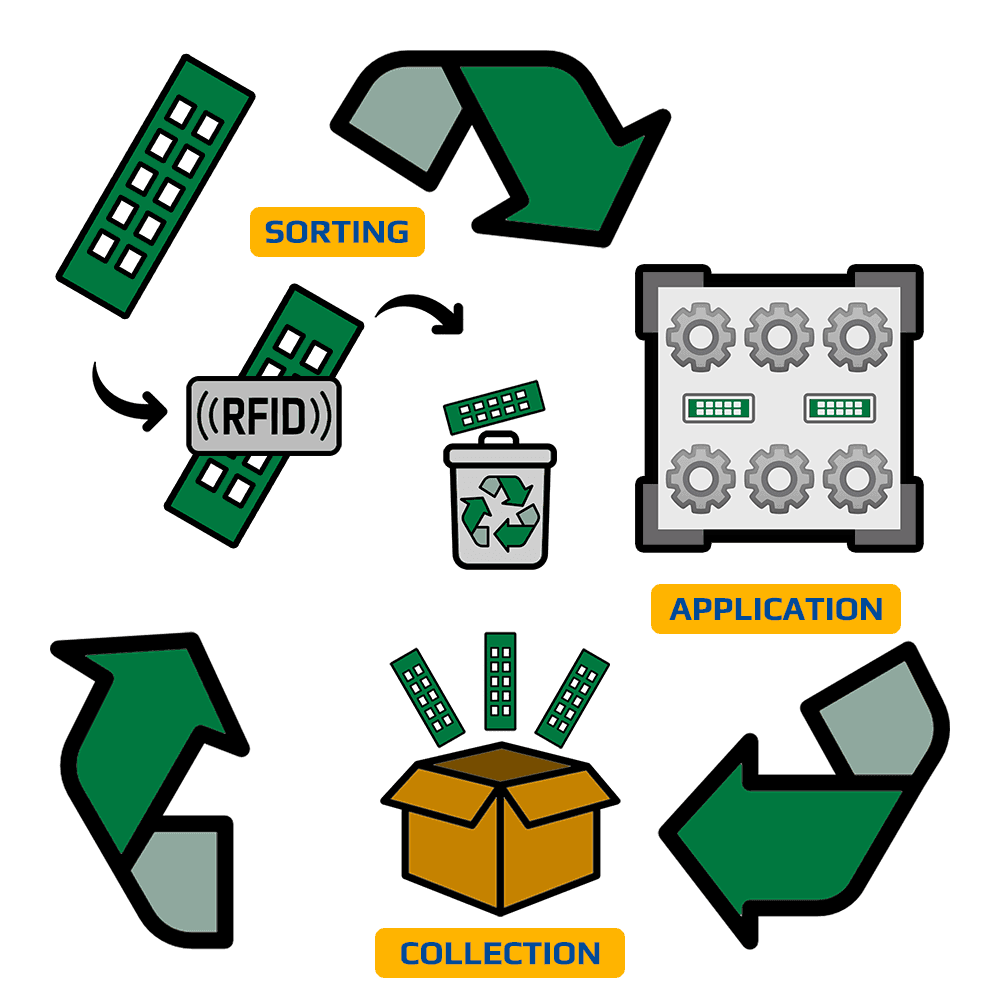

GreenVCI develops durable, multi-use VCI solutions engineered for repeated protection cycles. Our powders, emitters, sachets, and diffusers are designed to be collected, inspected, and reused, which significantly reducing waste and lowering lifecycle costs for customers. This supports circular manufacturing practices and extends material value without compromising corrosion performance.

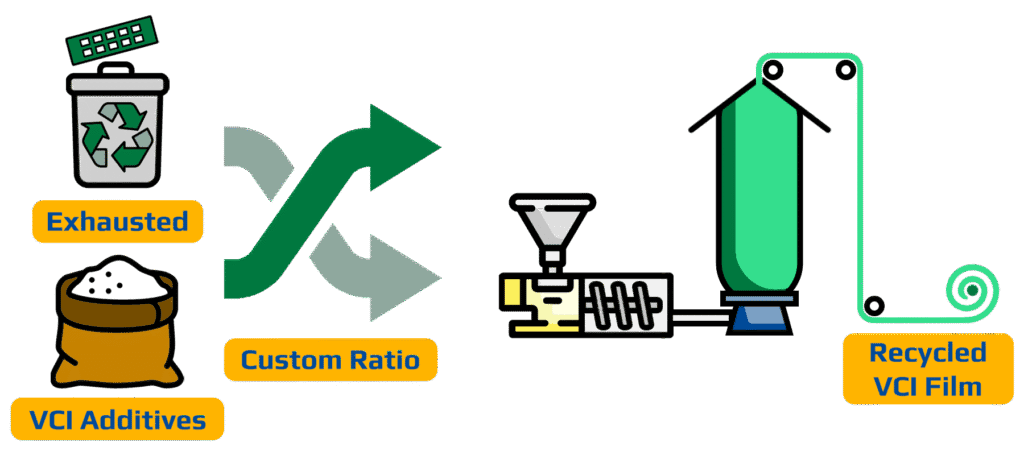

Many GreenVCI products, including films and packaging components, are fully recyclable within our expanding global closed-loop system. Used VCI materials are recovered, mechanically recycled, and repurposed as feedstock for new corrosion-protection products. This process reduces plastic waste, conserves resources, and helps clients meet their sustainability and compliance goals.

GreenVCI’s biodegradable VCI chemistries are formulated from plant-based, food-safe raw materials designed to break down naturally after use. Our materials have demonstrated high biodegradation rates in international testing standards, providing strong vapor-phase corrosion protection while supporting environmentally responsible disposal and product life cycles.

Trusted by global OEMs and Tier 1 suppliers, GreenVCI supports KD (CKD/SKD/DKD) part protection for cross-border assembly and long-distance logistics. Our VCI films, papers, powders, and devices safeguard thousands of components during packing, ocean transport, and warehouse storage, ensuring rust-free delivery and streamlined assembly operations.

GreenVCI supports the deep tech industry by protecting high value components used in artificial intelligence systems, data centers, robotics, semiconductors and advanced electronics. Our VCI solutions safeguard precision parts circuit assemblies’ connectors and mechanical modules from corrosion during manufacturing, storage and global shipment.

GreenVCI supports heavy equipment remanufacturing, refurbishment, and long-term storage with eco-friendly cleaners, rust removers, and VCI packaging solutions. Our products help extend machinery life, reduce downtime, and maintain the integrity of engines, hydraulic systems, and structural components throughout repair, rebuilding, and shipment.

From upstream to downstream operations, GreenVCI protects pipelines, valves, compressors, tanks, and refinery equipment from corrosion during hydrostatic testing, lay-up, shutdowns, and international export. Our vapor-phase inhibitors are engineered for high-moisture, high-salinity, and extreme environments, maintaining asset integrity and reducing costly maintenance.

GreenVCI supplies MIL-SPEC compliant VCI materials for aerospace components, ground vehicles, naval systems, and long-term strategic storage. As an approved vendor in major defense procurement systems, we provide preservation solutions used for deployment, cross-border shipment, and long-term readiness of mission-critical equipment.

The shipping industry faces constant exposure to salt, humidity, and temperature fluctuations. GreenVCI protects ship components, cargo, pipelines, engines, and spare parts using vapor-phase inhibitors that form a protective molecular layer inside packaging, containers, engine housings, and enclosed systems. Our solutions maintain corrosion-free equipment across ocean voyages, shipyard operations, and global marine logistics networks.