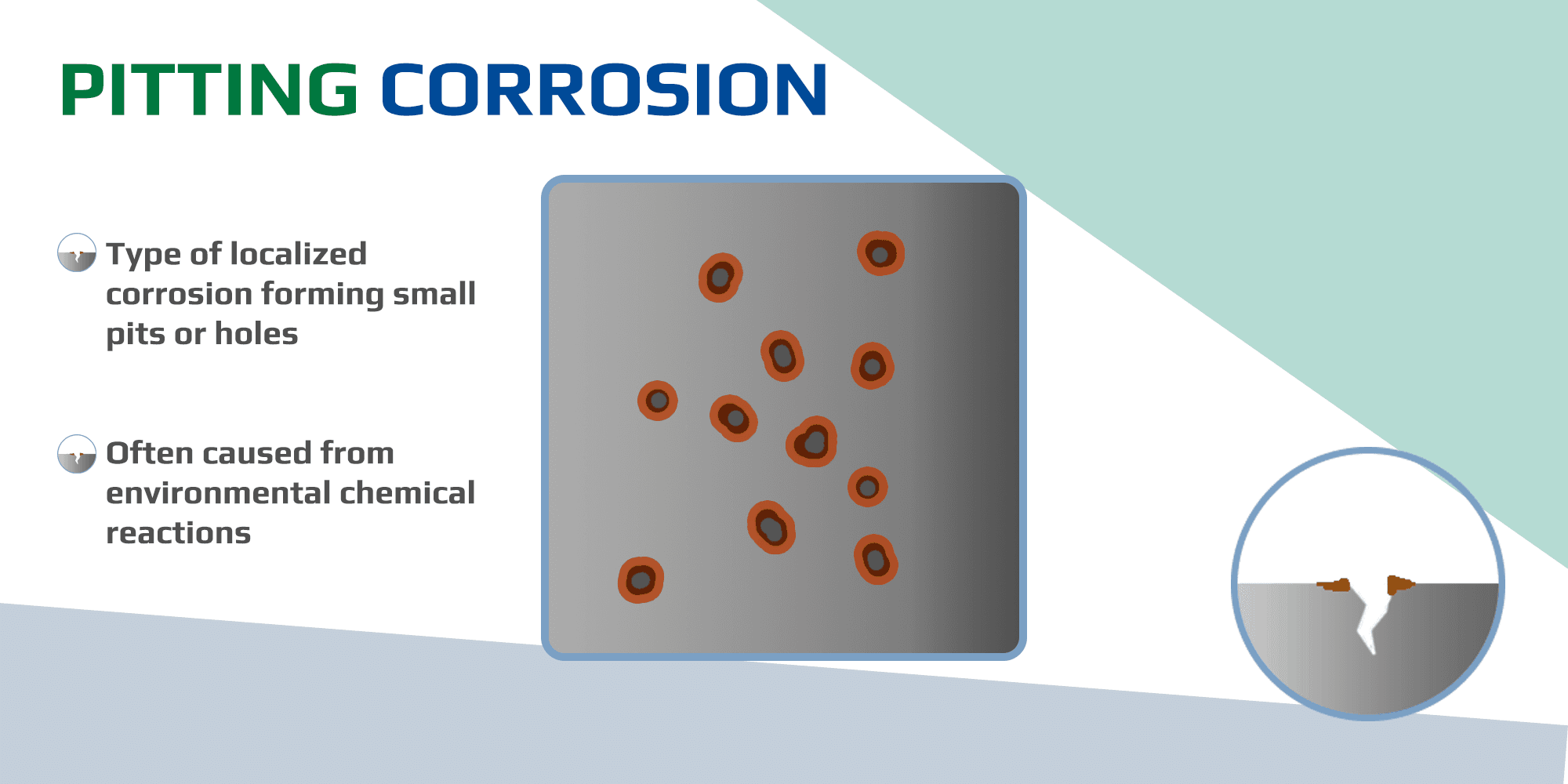

Pitting corrosion is a deceptive and dangerous form of localized corrosion that affects metals, leading to the formation of small pits or holes on the surface. Unlike uniform corrosion, which spreads evenly across a material (as discussed in our previous post on uniform corrosion), pitting can occur unpredictably and penetrate deeply, compromising structural integrity without widespread visible damage.

What is Pitting Corrosion?

Pitting corrosion is a type of localized attack where small, discrete pits form on a metal surface, often in passive metals like stainless steel, aluminum, or alloys. These pits can grow rapidly inward, creating holes that weaken the material. It’s particularly insidious because the surface may appear intact while severe damage occurs beneath.

Causes of Pitting Corrosion

Several environmental and material factors trigger pitting corrosion:

- Chloride Ions: Common in saltwater or de-icing salts, breaking down protective oxide layers.

- Acidic Environments: Low pH levels accelerate localized attacks.

- Oxygen Depletion: Areas with low oxygen, like crevices, promote pit initiation.

- Temperature Fluctuations: Higher temperatures increase reaction rates.

- Surface Defects: Scratches or impurities act as starting points for pits.

Effects of Pitting Corrosion

The consequences of pitting can be severe and costly:

- Structural Weakness: Deep pits lead to leaks, fractures, or failures in pipes and tanks.

- Reduced Lifespan: Accelerates material degradation in critical applications.

- Safety Risks: In industries like oil & gas or aerospace, it can cause catastrophic failures.

- Economic Impact: Higher repair and replacement costs due to hidden damage.

Prevention with VCI Technology

Volatile Corrosion Inhibitor (VCI) technology is a proven method to combat pitting corrosion. GreenVCI’s VCI products release vapor-phase inhibitors that form a protective molecular layer on metal surfaces, even in hard-to-reach areas, blocking environmental triggers like moisture and chlorides. Key benefits include:

- Cost-Effective: Reduces long-term maintenance expenses.

- Eco-Friendly: Biodegradable, non-toxic, and free from harmful chemicals.

- Versatile: Ideal for automotive, defense, and energy sectors.

- Sustainable: Supports recyclable and reusable packaging solutions.

By integrating GreenVCI’s innovative VCI solutions, you can safeguard metals against both pitting and other corrosion types like uniform corrosion.

Conclusion

Pitting corrosion presents unique challenges due to its localized and hidden nature, but understanding its causes and effects empowers proactive prevention. Leverage GreenVCI’s advanced VCI technology for reliable, green protection. Visit GreenVCI today to explore our corrosion inhibitor solutions and keep your assets pit-free.