Material choice critical for corrosion resistance.

Metal types vary in environmental compatibility.

Strategic selection enhances durability, reduces costs.

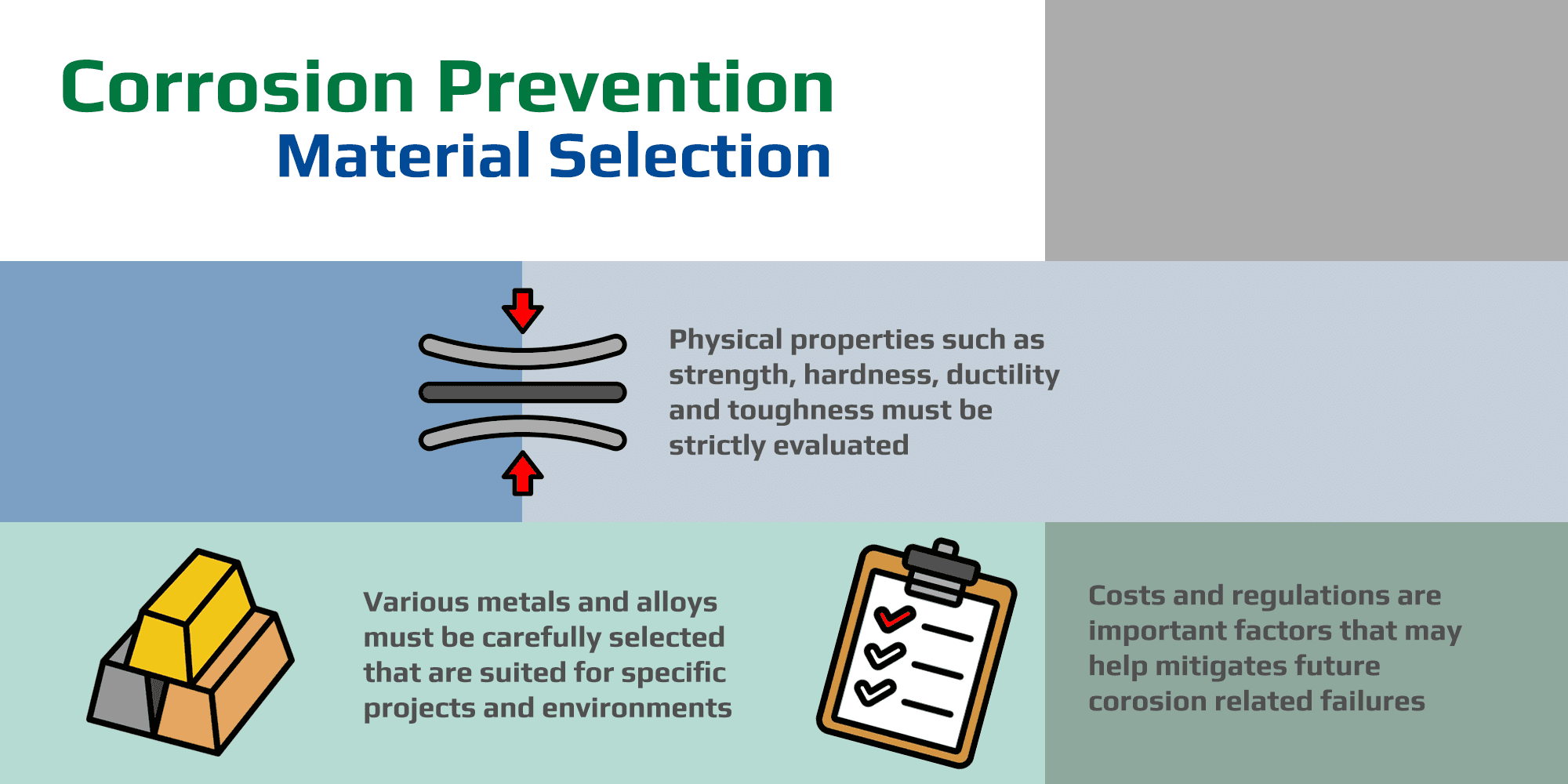

Importance of Material Selection

Selecting corrosion-resistant metals is essential to prevent structural failures, safety risks, and costly downtime. The right material ensures compatibility with specific environments, extending product lifespan.

Key Metals for Corrosion Resistance

Stainless Steel: Chromium forms a protective oxide layer. Grade 316, with molybdenum, resists chloride-rich environments like seawater.

Aluminum: Lightweight, forms oxide layer, ideal for atmospheric conditions but prone to pitting in chlorides.

Copper Alloys: Develop protective patina, suitable for marine and plumbing applications.

Nickel Alloys: Resist high-temperature corrosion, used in chemical processing and aerospace.

Titanium: Exceptional resistance via stable oxide film, perfect for aggressive environments.

Carbon Steel: Cost-effective but corrosion-prone, often requires coatings or galvanization.

Factors in Selection

Consider environment (e.g., saltwater, acids), temperature, mechanical stress, and cost. Avoid galvanic corrosion by matching electrochemical potentials.

Complementary Protection

Coatings, cathodic protection, or Volatile Corrosion Inhibitors (VCIs) enhance material resistance, especially during storage or transport.