Notice

기화성방청 원리

2023.02.13

VCI: How does it work?

Volatile Corrosion Inhibitors, or VCI, are chemicals utilized to

shield metal surfaces from harm caused by water and other environmental

factors. In the modern day industrial and manufacturing world, the use

of VCI is a necessary part of the packaging process for many metal

components.

But what exactly are VCI and how do they work?

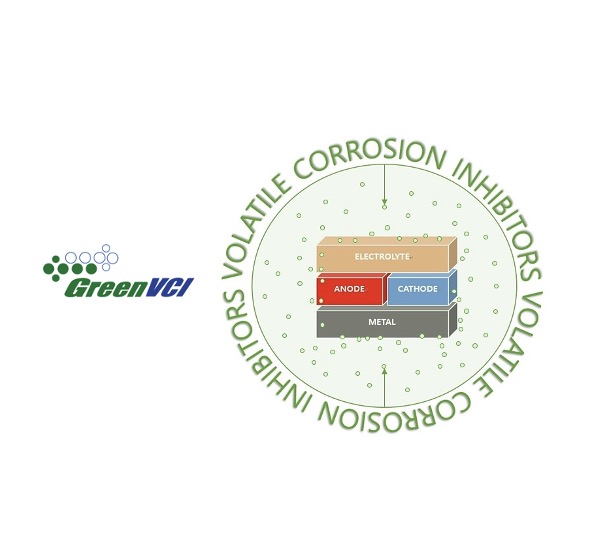

VCI is a type of corrosion inhibitor that releases vapor into the

atmosphere which forms a barrier over the metal's surface. The vapor

molecules in the VCI form a protective coating that blocks out moisture,

salt, and other corrosive elements. This provides long-term protection

against corrosion, even in extreme environmental conditions.

VCI can come in various forms such as films, papers, powder, and

liquids. The most common type is VCI film, which is utilized to

safeguard metal parts while in storage or being transported. The film is

put around the metal parts, and when the VCI molecules are released,

they generate a protective cover on the metal.

VCI is an excellent way to protect metallic surfaces from corrosion

as its efficacy is contingent on several components such as the metal

type, the environment, and the type of VCI used. For instance, the VCI

designed for ferrous metals, such as iron and steel, is different from

that intended for non-ferrous metals, like brass, copper, and aluminum,

as the latter include different VCI molecules to guard the metals from

corroding.

In summary, VCI is an effective defense against corrosion, as it

creates a defensive film on the metal surface by releasing vapors into

the atmosphere. Whether you need to shield your metallic parts during

storage or shipment, VCI is an ideal choice and will provide long-term

protection.

KR

KR