Fretting corrosion is an insidious form of localized corrosion that combines mechanical wear with oxidative damage, often leading to rust formation in metal components subjected to small oscillatory movements under load. Unlike crevice corrosion, which occurs in narrow gaps with restricted oxygen, fretting corrosion thrives at contact interfaces where vibrations or cyclic motions remove protective oxide layers, resulting in hidden rust and degradation that can compromise mechanical reliability.

What is Fretting Corrosion?

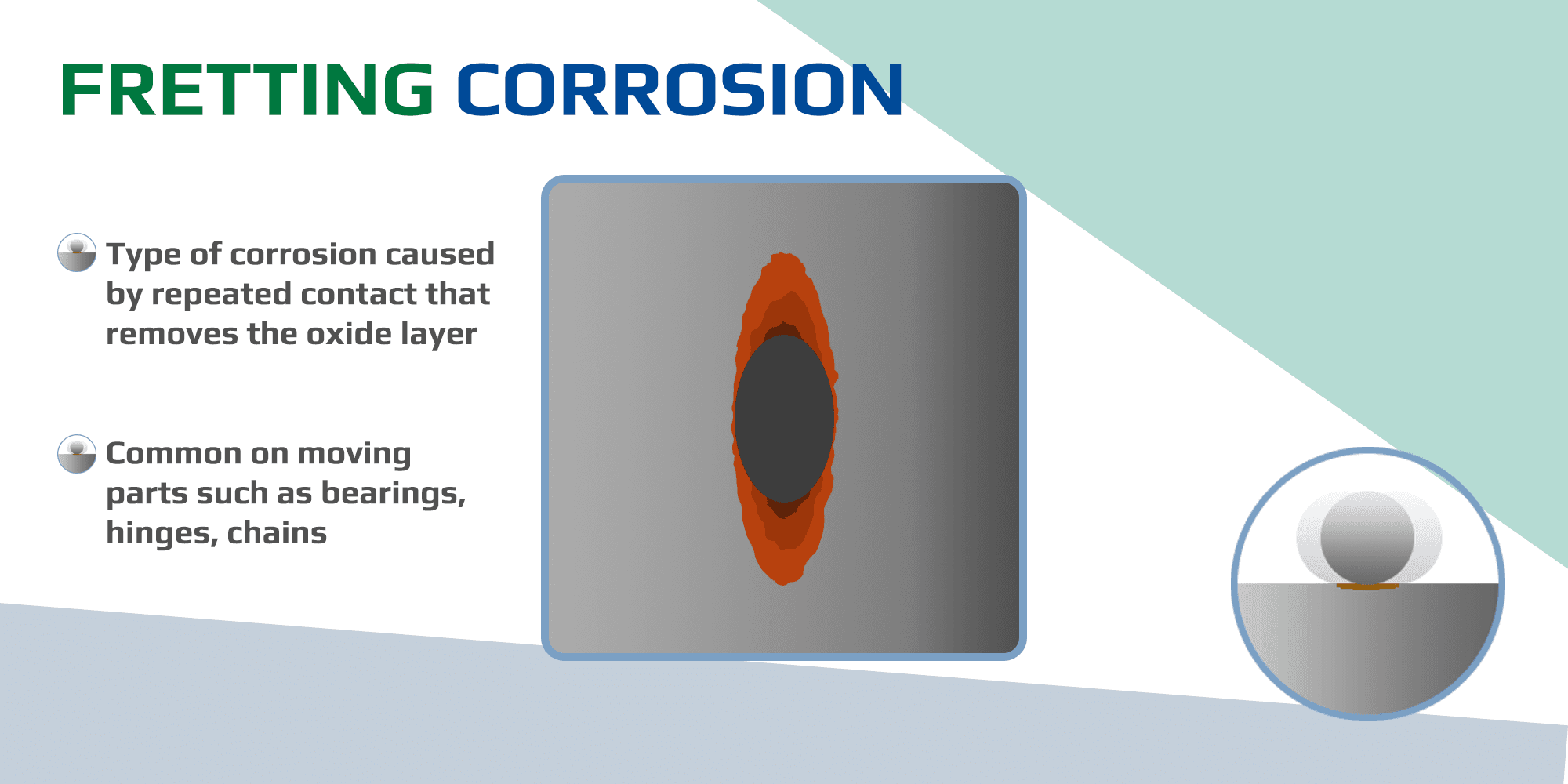

Fretting corrosion is a type of localized corrosion that arises from repeated micro-scale sliding between two contacting metal surfaces under compressive stress, typically with displacements less than 100-200 micrometers. This action abrades the passive oxide film on metals, exposing fresh surfaces to oxygen, moisture, and contaminants, which initiates electrochemical reactions and rust in ferrous materials like steel. It commonly affects alloys such as stainless steel, aluminum, and titanium, appearing as fine powdery debris, surface pitting, or reddish-brown rust stains. Often concealed in assembled parts like bearings, hinges, or chains, it can be hard to detect early, with symptoms including increased friction, noise, or vibration in operation.

Causes of Fretting Corrosion

Several factors contribute to the initiation and progression of fretting corrosion:

- Micro-Motions and Vibrations: Small oscillations from operational loads, thermal expansion, or external vibrations cause repeated contact, preventing oxide layer reformation and promoting rust.

- Contact Pressure: High compressive forces at interfaces amplify abrasion, especially in unlubricated or misaligned components, accelerating rust in humid environments.

- Environmental Conditions: Exposure to moisture, salts, pollutants, or oxygen creates aggressive conditions; chlorides, for example, intensify rust formation in industrial or marine settings.

- Material Susceptibility: Metals with thin or unstable oxide layers, such as certain steels, are more vulnerable, while hardness mismatches between surfaces generate more debris and rust.

- Design and Assembly Flaws: Tight tolerances without adequate damping or flexibility trap wear particles, fostering ongoing fretting and rust buildup.

Effects of Fretting Corrosion

The impacts of fretting corrosion can be significant and often unanticipated:

- Surface Damage and Rust: Results in pitting, scarring, and rust accumulation, which raises friction and can lead to seizure in moving parts like bearings or hinges.

- Fatigue Crack Initiation: Creates stress risers that evolve into cracks, diminishing fatigue life and risking structural failures under cyclic loads.

- Reduced Performance: In systems like chains or electrical connectors, it causes inefficiencies, such as higher resistance or signal loss, leading to downtime.

- Safety Risks: In critical industries like aerospace, automotive, or marine, fretting-induced rust and wear can trigger sudden breakdowns, endangering operations.

- Economic Costs: Drives up maintenance expenses through inspections, repairs, and part replacements, particularly for rust-hidden damage.

Prevention with VCI Technology

Volatile Corrosion Inhibitor (VCI) technology offers an effective defense against fretting corrosion and associated rust. GreenVCI’s VCI products release vapor-phase inhibitors that infiltrate even the most confined contact areas, creating a molecular shield on metal surfaces to block moisture, oxygen, and corrosive agents like chlorides. This is particularly beneficial for protecting vibrating or assembled components without disassembly. Key advantages include:

- Cost-Effective: Reduces repair frequency and prolongs asset life by preventing rust and wear.

- Eco-Friendly: Features biodegradable, non-toxic formulas that support sustainable practices.

- Versatile: Applicable across sectors such as manufacturing, transportation, and energy.

- Comprehensive: Delivers protection in inaccessible spots, complementing other methods like lubrication or coatings.

By integrating GreenVCI’s VCI solutions, you can safeguard against fretting corrosion alongside related issues like uniform and fatigue corrosion.

Conclusion

Fretting corrosion poses unique challenges due to its mechanical-corrosive synergy and concealed rust development, but understanding its causes and effects enables proactive prevention. Embrace GreenVCI’s innovative VCI technology for reliable, eco-conscious protection. Explore our lineup of corrosion inhibitors at GreenVCI to keep your metals rust-free and resilient.