Fatigue corrosion, also known as corrosion fatigue, is a sneaky culprit behind unexpected failures in metal components subjected to repeated stress in harsh environments. Unlike crevice corrosion, which hides in tight gaps and restricted oxygen zones (as we covered in our guide on crevice corrosion), fatigue corrosion teams up cyclic mechanical loading with corrosive agents—like moisture, salts, or even everyday rust—to accelerate crack growth. This combo erodes the fatigue life of metals far quicker than either factor alone, turning reliable structures into ticking time bombs.

What is Fatigue Corrosion?

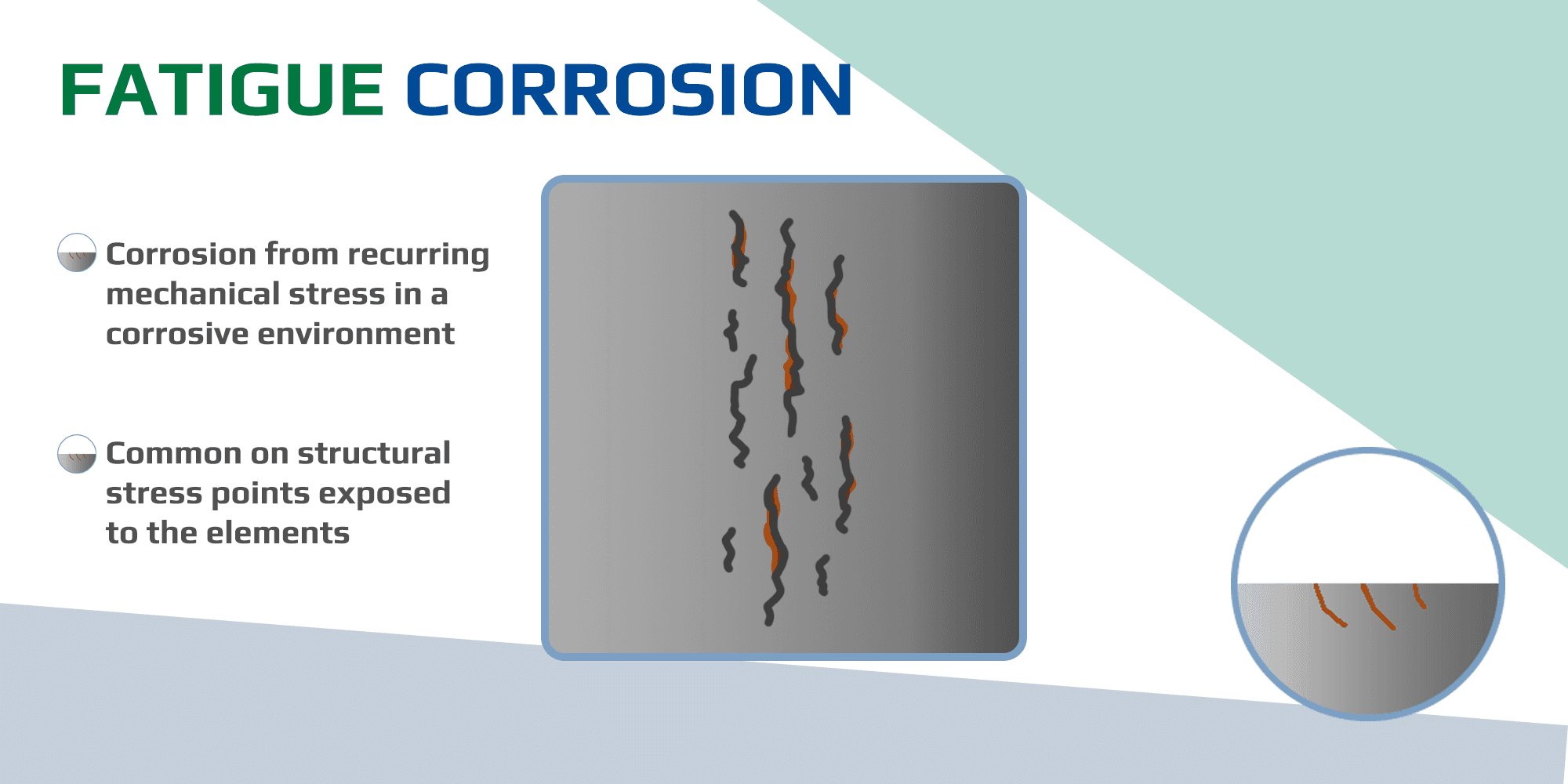

Fatigue corrosion occurs when metals endure repeated cycles of loading and unloading—think vibrations from machinery, waves battering offshore platforms, or traffic pounding bridges—while exposed to a corrosive atmosphere. The result? Micro-cracks form and propagate faster due to the corrosive attack, often manifesting as rust on iron-based alloys or oxide pitting on others. This isn’t just about visible rust; it’s the hidden synergy that drops a material’s endurance limit, making even high-strength steels vulnerable. Engineers often spot it in aerospace parts, marine hardware, and industrial piping, where it can start from tiny surface flaws as small as 10-50 micrometers and snowball under loads below the yield strength.

Causes of Fatigue Corrosion

A perfect storm of mechanical and chemical forces drives fatigue corrosion. Here’s what typically sets it off:

- Cyclic Stress Patterns: Low-frequency vibrations or flexing (e.g., 1-10 Hz) allow more time for corrosive reactions between cycles, worsening crack tips—unlike high-speed fatigue, which might outpace corrosion.

- Corrosive Environments: Exposure to moisture, chlorides, acids, or humid air promotes electrochemical reactions; even atmospheric rust from oxygen and water vapor can kickstart the process in ferrous metals.

- Surface Imperfections: Pre-existing pits, scratches, or manufacturing defects act as stress concentrators, inviting localized rust and accelerating fatigue crack initiation.

- Material Susceptibility: High-strength alloys like tempered steels or aluminum lose their edge in wet or salty conditions, as protective films break down under repeated stress.

- Environmental Factors: Temperature swings, pollutants, or poor drainage amplify ion mobility and rust formation, especially in outdoor or marine settings.

Effects of Fatigue Corrosion

The fallout from fatigue corrosion hits hard, often catching operators off guard with sudden, brittle failures:

- Rapid Crack Propagation: Cracks grow exponentially, leading to leaks in pressure vessels, fractures in turbine blades, or collapses in load-bearing beams—far outpacing dry fatigue alone.

- Reduced Component Lifespan: What might last millions of cycles in air could fail after thousands in a rusty, corrosive setup, hiking replacement costs in high-stakes industries.

- Safety and Reliability Risks: In aviation, shipping, or energy sectors, it spells disaster—from engine malfunctions to structural breaches—endangering lives and operations.

- Economic Toll: Beyond repairs, it drives up downtime, inspections, and insurance premiums, with hidden rust damage often multiplying expenses in hard-to-reach spots.

Prevention with VCI Technology

Enter Volatile Corrosion Inhibitor (VCI) technology from GreenVCI—a game-changer for shielding against fatigue corrosion without bulky coatings or constant monitoring. Our VCI formulations release vapor-phase molecules that migrate to stressed metal surfaces, creating a thin, rust-repelling film that blocks moisture, oxygen, and salts right where cracks might form. Ideal for dynamic parts under cyclic loads, this approach penetrates assemblies and protects during storage, transport, or in-service use. Why choose GreenVCI?

- Proactive Defense: Neutralizes corrosive agents before they team up with stress, extending fatigue life by 2-5x in tests on steels and alloys.

- Sustainable Edge: Our nitrite-free VCI products are eco-friendly and recyclable, fitting seamlessly into green initiatives while curbing rust-related waste.

- Industry-Ready Versatility: Tailored for automotive, oil & gas, defense, and construction—think wrapping bridge girders or packaging aircraft fittings.

- Hassle-Free Application: No disassembly needed; just deploy emitters or films for all-around coverage, even in vibrating or flexing components.

Pair VCI with smart design tweaks like rounded edges to ease stress points, and you’ll fortify against fatigue corrosion alongside threats from the broader spectrum in our 10 Types of Corrosion guide.

Conclusion

Fatigue corrosion thrives on the deadly dance between relentless stress and sneaky corrosive elements like rust, but armed with insight into its triggers and tolls, you can stay steps ahead. GreenVCI’s innovative VCI solutions deliver reliable, planet-friendly armor to keep your metals fatigue-free and rust-resistant. Ready to safeguard your assets? Explore our lineup of corrosion inhibitors and rust preventives at GreenVCI today—because when it comes to protection, trust the green way.