Crevice corrosion is a insidious form of localized corrosion that targets metals in narrow gaps or confined spaces, leading to accelerated material degradation. Unlike uniform corrosion, which affects surfaces evenly (as explored in our article on uniform corrosion), or pitting corrosion, which creates isolated holes (detailed in our post on pitting corrosion), crevice corrosion thrives in occluded areas where oxygen flow is restricted, often resulting in hidden damage that can compromise structural integrity.

What is Crevice Corrosion?

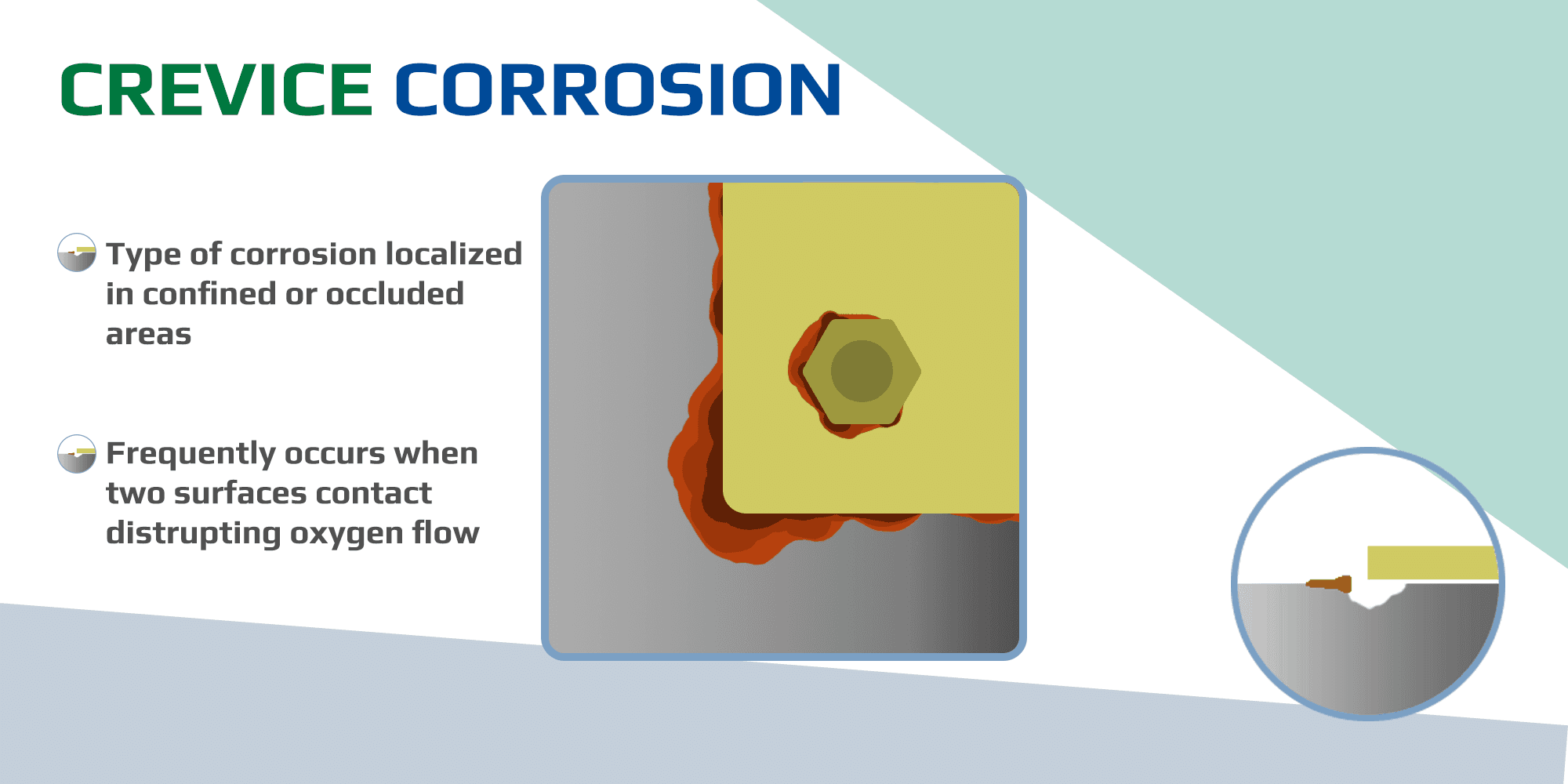

Crevice corrosion is a type of localized corrosion that occurs in confined or occluded areas, such as gaps between metal surfaces, under deposits, or in joints like bolts, rivets, and gaskets. It frequently happens when two surfaces come into contact, disrupting oxygen flow and creating differential aeration cells. This leads to anodic dissolution in the oxygen-deprived crevice, while the surrounding areas remain cathodic and protected. Common in alloys like stainless steel and aluminum, it can initiate from tiny openings as small as a few micrometers, making it challenging to detect early.

Causes of Crevice Corrosion

Several factors contribute to the initiation and progression of crevice corrosion:

- Restricted Oxygen Access: Narrow gaps limit oxygen diffusion, creating acidic, chloride-rich environments inside the crevice.

- Moisture and Contaminants: Accumulation of water, salts, or pollutants in confined spaces accelerates electrochemical reactions.

- Material Composition: Susceptible in passive metals where protective oxide layers break down in low-oxygen zones.

- Temperature Variations: Elevated temperatures enhance ion mobility and reaction rates within crevices.

- Design Flaws: Poorly designed joints, welds, or assemblies that trap moisture and debris.

Effects of Crevice Corrosion

The impacts of crevice corrosion can be profound and often unexpected:

- Structural Compromise: Deep penetration in hidden areas leads to leaks, cracks, or failures in pipelines, fasteners, and equipment.

- Shortened Service Life: Accelerates wear in critical components, reducing overall durability.

- Safety Hazards: In sectors like marine, chemical processing, or infrastructure, it poses risks of sudden breakdowns.

- Financial Burden: Increases inspection, repair, and downtime costs due to difficult-to-access damage.

Prevention with VCI Technology

Volatile Corrosion Inhibitor (VCI) technology offers an effective shield against crevice corrosion. GreenVCI’s VCI products emit vapor-phase inhibitors that penetrate even the tightest crevices, forming a molecular barrier on metal surfaces to neutralize corrosive agents like moisture, oxygen, and chlorides. This is especially valuable for protecting complex assemblies. Key advantages include:

- Cost-Effective: Minimizes repair needs and extends asset longevity.

- Eco-Friendly: Biodegradable, non-toxic formulations that align with sustainable practices.

- Versatile: Suitable for industries including maritime, oil & gas, and manufacturing.

- Comprehensive: Provides protection in hard-to-reach areas without disassembly.

By adopting GreenVCI’s VCI solutions, you can defend against crevice corrosion alongside other forms like uniform and pitting corrosion.

Conclusion

Crevice corrosion poses unique risks due to its concealed and localized nature, but by grasping its causes and effects, proactive measures become possible. Embrace GreenVCI’s cutting-edge VCI technology for dependable, environmentally conscious protection. Discover our range of corrosion inhibitors at GreenVCI to maintain your metals crevice-free.