Info

VCI & MVTR: Their Synergy

2023.10.18

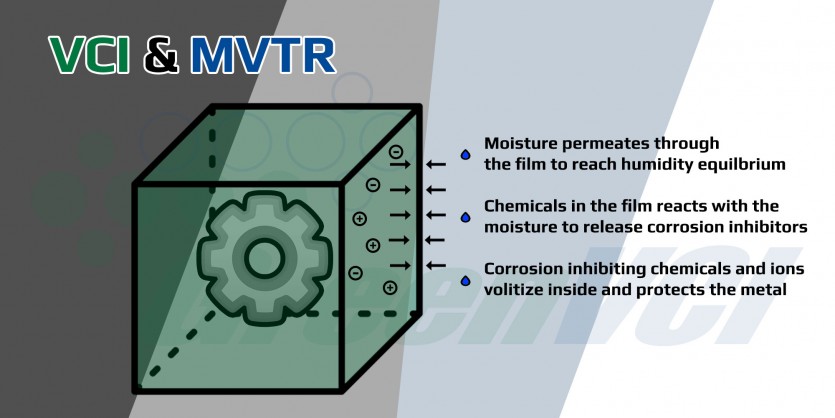

In the realm of moisture and metal, two crucial ideas come to the forefront: MVTR and VCI. Together, they combine to create a robust shield against corrosion. In this post, we'll investigate the collaborative efforts of these two concepts in safeguarding metal from the perils of rust and moisture.

1. Moisture Permeates Through the Film to Reach Humidity Equilibrium

MVTR, or Moisture Vapor Transmission Rate, is like the gatekeeper controlling the ingress of moisture. It operates on a simple principle: materials strive to reach humidity equilibrium with their surroundings. For metal, this equilibrium can spell trouble in the form of corrosion.

2. Chemicals in the Film React with Moisture to Release Corrosion Inhibitors

Imagine Vapor Corrosion Inhibitors (VCIs) as the unsung heroes of rust prevention. These agents are embedded within films or packaging materials and leap into action when humidity levels rise.

3. Corrosion Inhibiting Chemicals and Ions Volatilize Inside and Protect the Metal

When humidity levels fluctuate, VCIs release more inhibitors, fortifying the protective layer. Conversely, during drier periods, the release may slow down, preserving their corrosion-fighting power. This adaptability ensures that metals remain shielded against corrosion, come rain or shine.

To sum up, the collaboration between MVTR and VCI offers a strong protection against the combined threats of moisture and rust. Industries dependent on metal can harness these principles to guarantee their products stay free from rust and resilient, even in the face of nature's unrelenting challenges.

EN

EN