Info

VCI Supplements: VCI Desiccant

2023.08.04

VCI Supplements: VCI Desiccant

Q1: When are the VCI supplements such as VCI desiccants recommended for use based on GreenVCI’s technical standards and case studies?

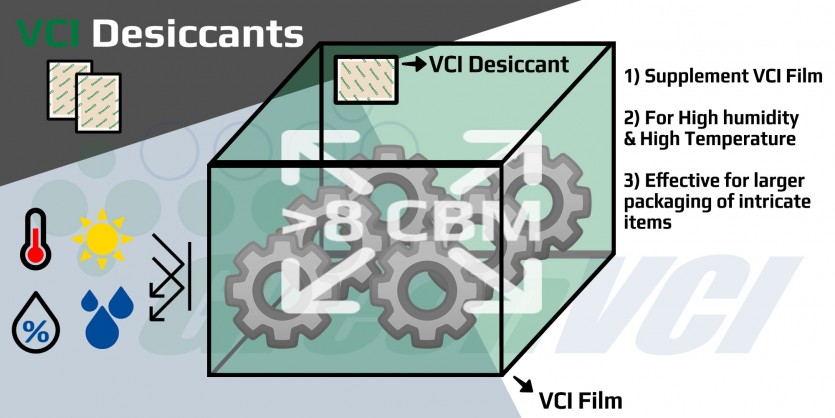

A1: VCI (Volatile Corrosion Inhibitor) supplements, like VCI desiccants, offer an extra layer of defense in environments where metals face humidity, moisture, or corrosive elements. When using VCI films to package large solid items, no additional VCI is necessary. However, for complex structures or gears with uneven surfaces and holes, VCI powder packs or VCI desiccants are valuable supplements to enhance corrosion inhibition. For containers and boxes larger than 8 CBM, adding additional VCI supplement is advisable, ensuring optimal protection. VCI desiccants are commonly employed in various scenarios during packaging and transportation, long-term storage, automotive, electronics, military, and industrial equipment. Including VCI desiccants in packaging materials shields metal items during transit, controlling moisture levels and preventing harmful condensation.

Q2: How do VCI desiccants work in a high-temperature and high-humidity environment?

A2: In a high-temperature and high-humidity environments, the reactivity of metal ions increases and the MVTR (moisture vapor transmission rate) of the VCI film chemicals also increases, making it difficult to protect the item only with VCI films. Using VCI desiccants which inhibit corrosion as well as absorb moisture exposed in the air/atmosphere supplement effectively the VCI film’s inhibiting function.

Q3: How long do VCI desiccants provide corrosion inhibition for?

A3: VCI desiccants are for short term protection of less than six months.

https://www.greenvci.co.th/greenvci-vci-supplements-vci-desiccant/

EN

EN