Info

Archives

VCI Film Packaging Tip

2023.07.08

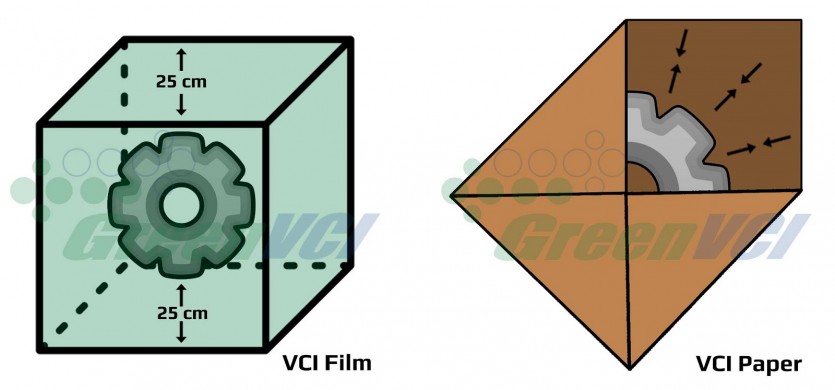

For VCI film packaging, it is ideal to keep a gap of 3~25cm between the packaging object and VCI film for optimal anti-corrosion effect. Why?

Answer:

It is because the gap is calculated to maintain an appropriate distance/space between the product that needs to be corrosion-protected and the film, so that the vaporized particles from the film can effectively disperse in the space to form a covalent bond on the entire metal surface.

However, for VCI Paper, owing to its instant volatility, it is most economical to apply the packaging material as close as possible to the product to reduce space as well as transportation costs. (In comparison to VCI Film, though, the lasting effect of VCI Paper's anti-corrosion functionality is inevitably compromised)

https://www.greenvci.co.th/greenvci-vci-film-packaging-tip/

Answer:

It is because the gap is calculated to maintain an appropriate distance/space between the product that needs to be corrosion-protected and the film, so that the vaporized particles from the film can effectively disperse in the space to form a covalent bond on the entire metal surface.

However, for VCI Paper, owing to its instant volatility, it is most economical to apply the packaging material as close as possible to the product to reduce space as well as transportation costs. (In comparison to VCI Film, though, the lasting effect of VCI Paper's anti-corrosion functionality is inevitably compromised)

https://www.greenvci.co.th/greenvci-vci-film-packaging-tip/

EN

EN