GreenVCI®

The World-Class Anti-Corrosion & Quality Control Solution You Can Trust

Case Studies

What Does TRGS 615 Have to Do With VCI?

2022.11.13

What Does TRGS 615 Have to Do With VCI?

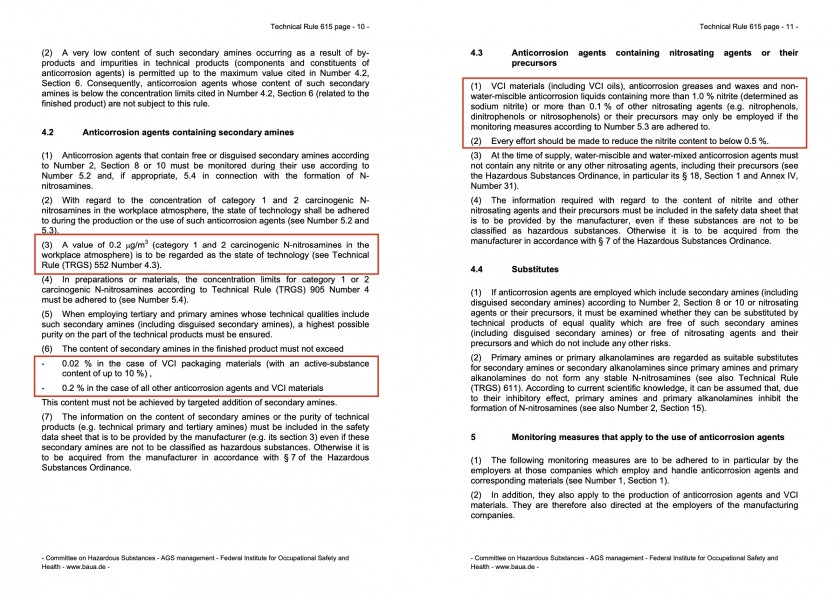

The German Technical Rules of Hazardous Substances 615 (TRGS 615) was announced by the Federal Ministry of Labour and Social Affairs in the Joint Ministerial Gazette (GMBI). TRGS 615 restricts the use of anticorrosion agents whose use can lead to the formation of N-nitrosamines.

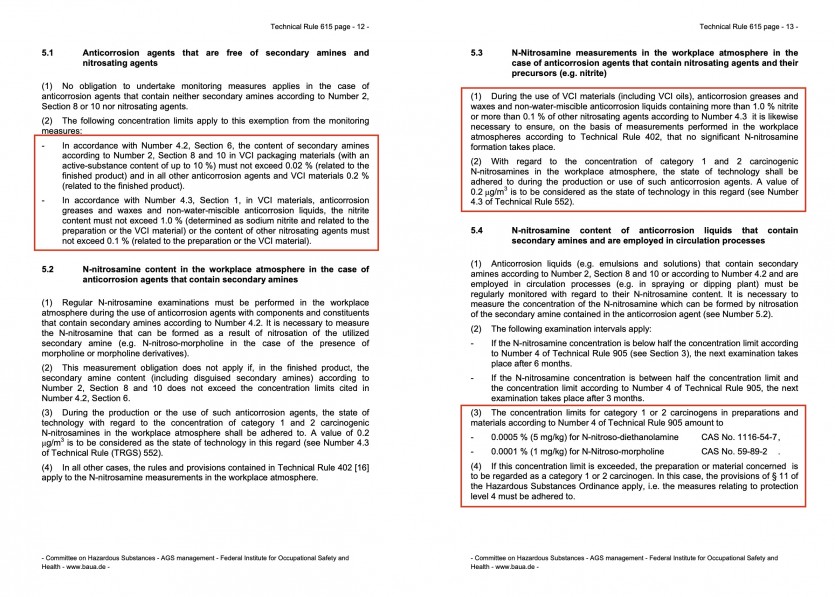

TRGS 615 states, "The content of secondary amines in finished product must not exceed 0.02% in the case of VCI packaging materials (with an active-substance content of up to 10%)" and "Every effort should be made to reduce the nitrite content to below 0.5 %".

VCI recipes containing nitrite secondary amines, such as the TRGS 615 regulated chemicals listed below, fall into this category.

TRGS 615 Regulated Chemicals

Sodium Nitrite CAS No. 7462-00-0

Potassium Nitrite CAS No. 7758-09-0

Morpholine CAS No. 110-91-8

N-nitroso-morpholine CAS No. 59-89-2

Dicylohexylamine CAS No. 101-83-7

N-nitroso-piperazine CAS No. 5632-47-3

N, N’-dinitroso-piperazine CAS No. 140-79-4

Diethanolamine (2,2’-iminodiethanol) CAS No. 111-42-2

Piperazine CAS No. 110-85-0

N-nitroso-diethanolamine (2,2’ –(nitrosoimino) bisethanol) CAS No. 1116-54-7

TRGS 615 restricts the use of anticorrosion agents that can lead to the formation of N-nitrosamines. When these nitrite-containing substances are combined with amines, it produces toxic substances called carcinogens, such as Nitrosamine, when it is inhaled or in contact with the human body.

TRGS 615 warns and exposes the danger of being in contact with and inhaling secondary amines and nitrites in VCI since May 2007. Sadly, although most VCI producers and manufacturers are aware of its harmfulness and regulations, they cannot cope with the problems due to the lack of information, R&D development, and price point advantages offered through these harmful substances.

Most importantly, many VCI manufacturers and suppliers have limited choices because most of the companies they have been supplying VCI to have already approved and registered their previous VCI application specifications into their supply chain system. Changing the VCI application specifications that were already registered and functional from a company's perspective is not easy due to the long testing and approval process that needs to be repeated for the newly introduced VCI solutions. Unless the alternative VCI solution is green VCI with economical, stronger, and higher-quality benefits compared to its previous VCI predecessor, it is not in the customer’s best interest to purposely change.

The global manufacturing industry stands on the brink of disruption as the ESG framework transforms the industry and other fourth industrial revolution factors such as AI, robotics, and digitization. The companies that will survive this transition will be those that protect the environment, take care of everyone involved with their products, help their communities, and have strong corporate governance.

Chemical manufacturers are now under massive pressure and oversight to minimize industrial waste and carbon emissions and develop the most environmentally friendly yet effective products. Luckily, positive movements within the major automobile sectors force VCI manufacturers and suppliers to comply with TRGS 615. For example, the Volkswagen Group VCI packaging testing standard VW 50164 consists of seven main evaluation procedures. The first procedure before evaluating VCI performance and quality is to analyze the presence of secondary amines and nitrite according to the technical rules of TRGS 615.

GreenVCI R&D Co., Ltd. welcomes the opportunity to serve your company with green corrosion inhibitor products and solutions.

By: John Kim

Partner @ GreenVCI Solutions (USA)

#greenvci #VCI #trgs615 #nitrosamine #vw50164 #corrosioninhibitor

TRGS 615 URL:

https://www.baua.de/DE/Angebote/Rechtstexte-und-Technische-Regeln/Regelwerk/TRGS/TRGS-615.html

The German Technical Rules of Hazardous Substances 615 (TRGS 615) was announced by the Federal Ministry of Labour and Social Affairs in the Joint Ministerial Gazette (GMBI). TRGS 615 restricts the use of anticorrosion agents whose use can lead to the formation of N-nitrosamines.

TRGS 615 states, "The content of secondary amines in finished product must not exceed 0.02% in the case of VCI packaging materials (with an active-substance content of up to 10%)" and "Every effort should be made to reduce the nitrite content to below 0.5 %".

VCI recipes containing nitrite secondary amines, such as the TRGS 615 regulated chemicals listed below, fall into this category.

TRGS 615 Regulated Chemicals

Sodium Nitrite CAS No. 7462-00-0

Potassium Nitrite CAS No. 7758-09-0

Morpholine CAS No. 110-91-8

N-nitroso-morpholine CAS No. 59-89-2

Dicylohexylamine CAS No. 101-83-7

N-nitroso-piperazine CAS No. 5632-47-3

N, N’-dinitroso-piperazine CAS No. 140-79-4

Diethanolamine (2,2’-iminodiethanol) CAS No. 111-42-2

Piperazine CAS No. 110-85-0

N-nitroso-diethanolamine (2,2’ –(nitrosoimino) bisethanol) CAS No. 1116-54-7

TRGS 615 restricts the use of anticorrosion agents that can lead to the formation of N-nitrosamines. When these nitrite-containing substances are combined with amines, it produces toxic substances called carcinogens, such as Nitrosamine, when it is inhaled or in contact with the human body.

TRGS 615 warns and exposes the danger of being in contact with and inhaling secondary amines and nitrites in VCI since May 2007. Sadly, although most VCI producers and manufacturers are aware of its harmfulness and regulations, they cannot cope with the problems due to the lack of information, R&D development, and price point advantages offered through these harmful substances.

Most importantly, many VCI manufacturers and suppliers have limited choices because most of the companies they have been supplying VCI to have already approved and registered their previous VCI application specifications into their supply chain system. Changing the VCI application specifications that were already registered and functional from a company's perspective is not easy due to the long testing and approval process that needs to be repeated for the newly introduced VCI solutions. Unless the alternative VCI solution is green VCI with economical, stronger, and higher-quality benefits compared to its previous VCI predecessor, it is not in the customer’s best interest to purposely change.

The global manufacturing industry stands on the brink of disruption as the ESG framework transforms the industry and other fourth industrial revolution factors such as AI, robotics, and digitization. The companies that will survive this transition will be those that protect the environment, take care of everyone involved with their products, help their communities, and have strong corporate governance.

Chemical manufacturers are now under massive pressure and oversight to minimize industrial waste and carbon emissions and develop the most environmentally friendly yet effective products. Luckily, positive movements within the major automobile sectors force VCI manufacturers and suppliers to comply with TRGS 615. For example, the Volkswagen Group VCI packaging testing standard VW 50164 consists of seven main evaluation procedures. The first procedure before evaluating VCI performance and quality is to analyze the presence of secondary amines and nitrite according to the technical rules of TRGS 615.

GreenVCI R&D Co., Ltd. welcomes the opportunity to serve your company with green corrosion inhibitor products and solutions.

By: John Kim

Partner @ GreenVCI Solutions (USA)

#greenvci #VCI #trgs615 #nitrosamine #vw50164 #corrosioninhibitor

TRGS 615 URL:

https://www.baua.de/DE/Angebote/Rechtstexte-und-Technische-Regeln/Regelwerk/TRGS/TRGS-615.html

EN

EN