The future of corrosion protection starts here.

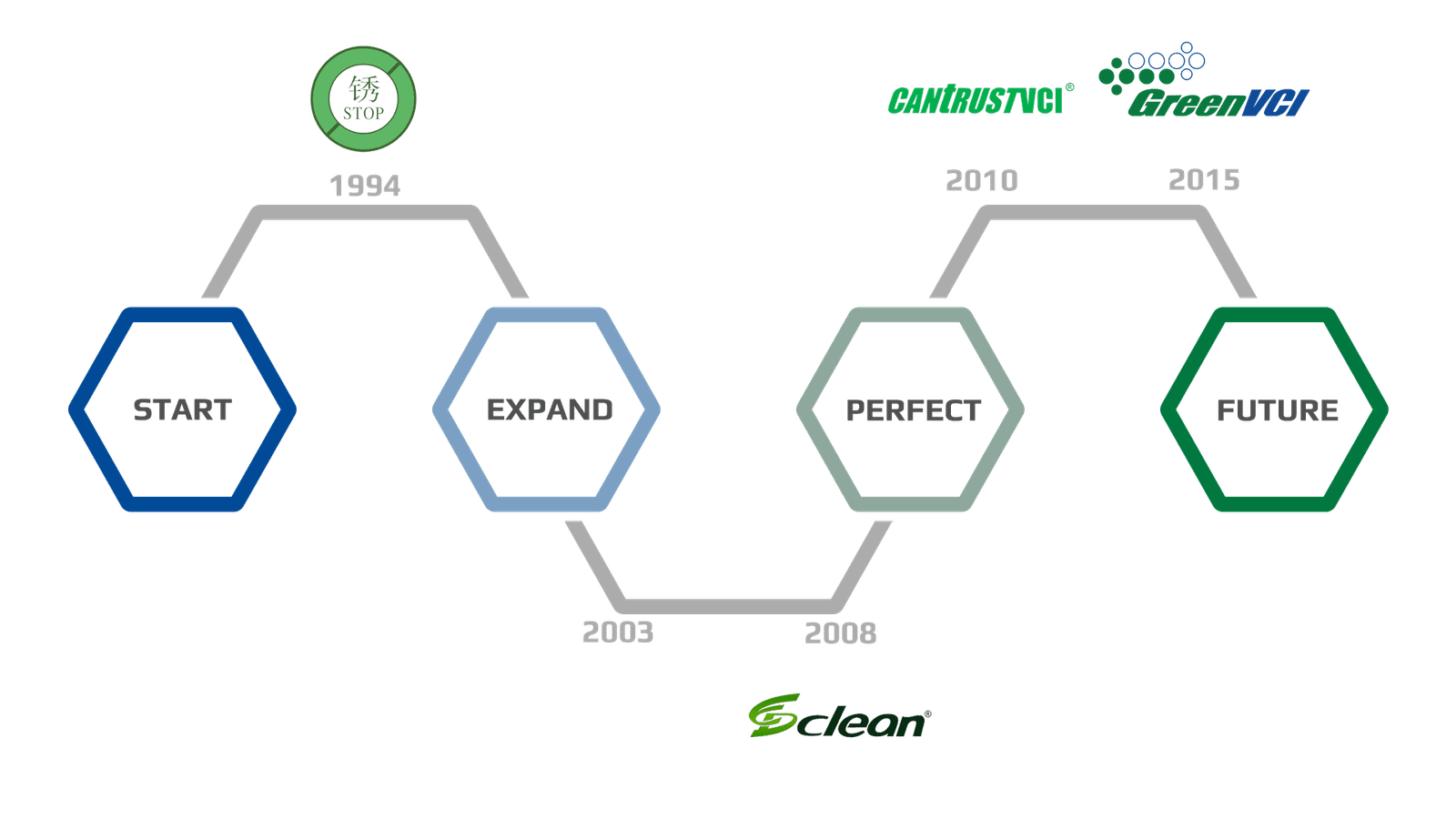

GreenVCI R&D Co. Ltd. (formerly John & Eundong Co. Ltd.), founded in 1994 as Eundong Industries, has evolved into a world-class provider of anti-corrosion and quality control solutions. Specializing in Volatile/Vapor Corrosion Inhibitors (VCI) technology—originally developed during World War II—GreenVCI has been at the forefront of corrosion protection innovation.

Adhering to our motto, “CAN TRUST IT CAN’T RUST,” we prioritize customer satisfaction by delivering environmentally friendly, socially responsible, and cost-effective solutions. Our products and services have earned acclaim from numerous global top brands and Fortune 500 companies.

In 1994, we launched our proprietary VCI product line, marking a major breakthrough in the Asian market. Our ongoing commitment to research and development has led to a robust portfolio of non-toxic, biodegradable, and food-grade corrosion protection products. These products meet the industry’s highest standards and have earned certifications for their quality and effectiveness.

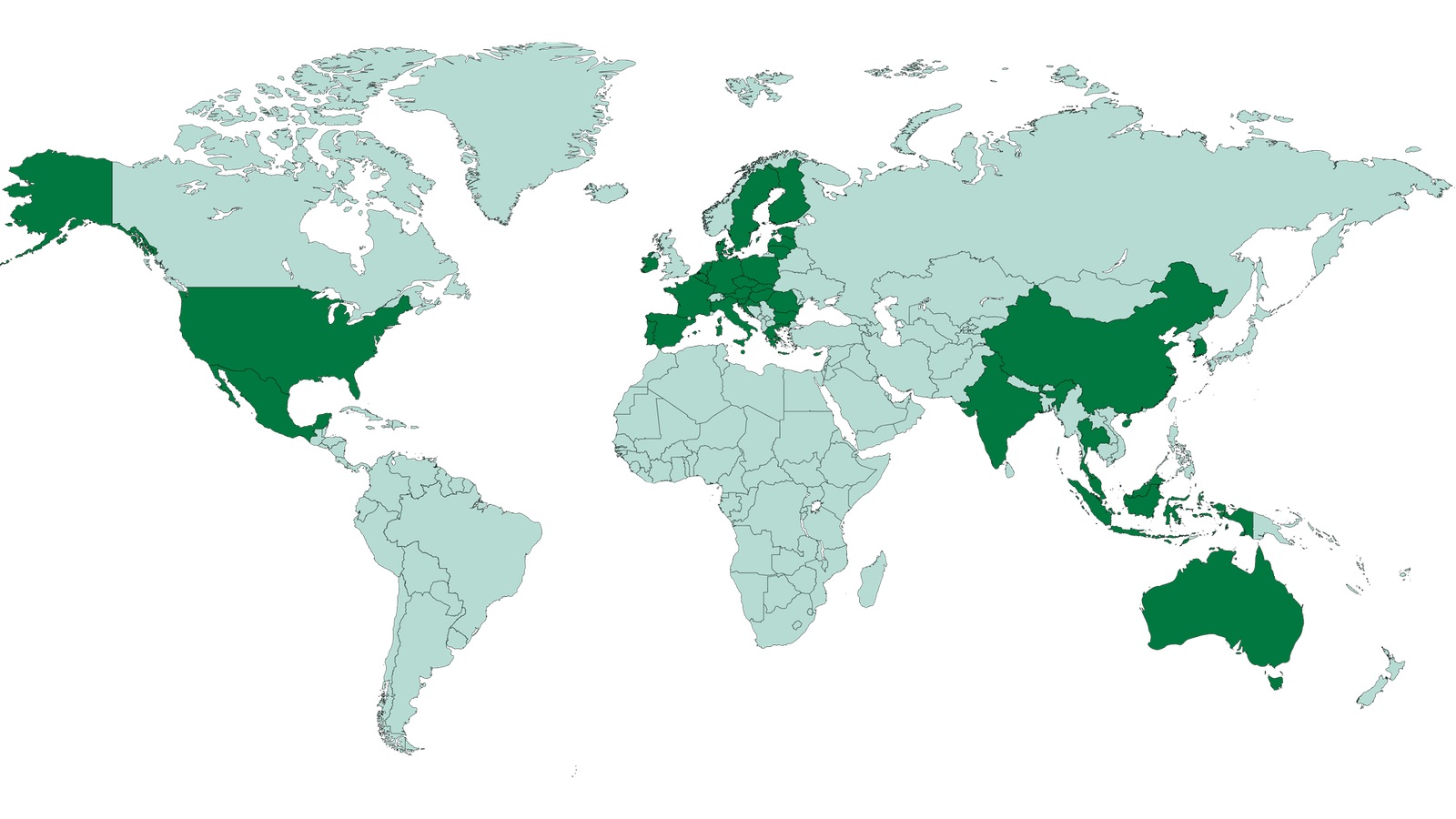

GreenVCI boasts an expansive international sales network with representative offices and local agents across Asia, the Americas, and Europe. These offices play a pivotal role in the sales and marketing of our products, leveraging a wealth of globally shared knowledge and data to serve regional needs effectively.

As we continue to grow, GreenVCI remains dedicated to innovation, customer satisfaction, and environmental stewardship, ensuring our solutions not only meet but exceed the expectations of our clients worldwide.

Redefining Corrosion Protection – Smarter, Safer, & Greener.

GreenVCI delivers biodegradable and readily biodegradable solutions to ensure minimal environmental impact.

Made from food-grade and plant-derived materials with zero hazardous chemicals without nitrites or secondary amines. Fully compliant with EU REACH (SVHC), RoHS, and TRGS 615.

Stronger protection, smarter solutions. Customizable for specific metals and durations, ensuring cost-effective, high-impact results.

Australia

China

EU

Germany

India

Indonesia

Malaysia

Mexico

Singapore

South Korea

Thailand

GreenVCI R&D Co., Ltd.

TEL +82) 31-8043-5568 | Email info@greenvci.com

Address 480-72, Jangan-ro, Jangan-myeon,

Hwaseong-si, Gyeonggi-do, Republic of Korea 18583