GreenVCI®

The World-Class Anti-Corrosion & Quality Control Solution You Can Trust

Case Studies

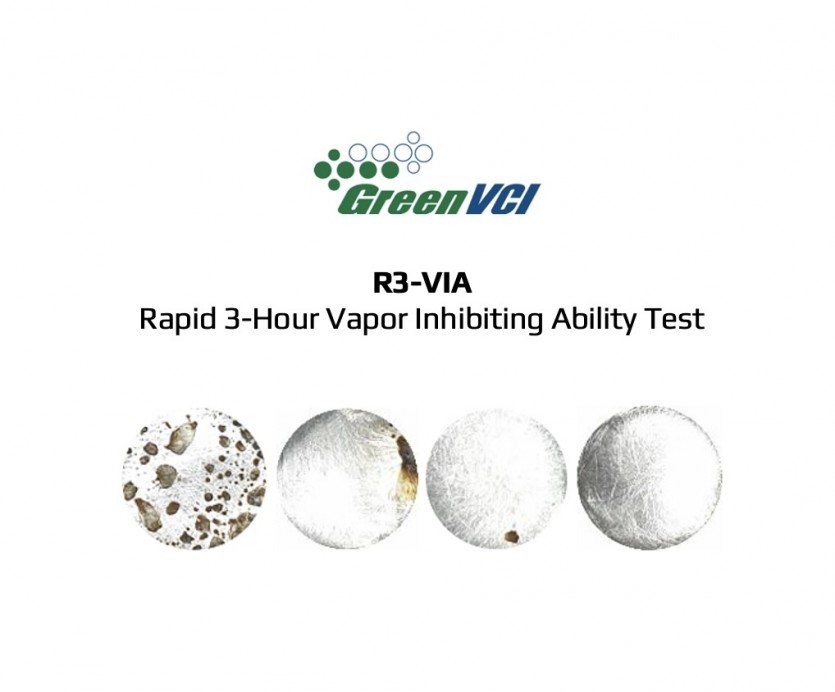

Introducing our Patent-Backed 3-Hour VIA Testing Method for VCI Film and VCI Paper

2022.12.06

Introducing Our Patent-Backed 3-Hour VIA Testing Method for VCI Film and Paper

The most widely accepted methods for testing VCI (vapor corrosion inhibitors) include the Salt Spray Test, Contact Corrosivity Climate Control Test, and Vapor Inhibiting Ability (VIA) tests from the US Department of Defense MIL-STD-3010 method 4031, NACE TM0208-2018, and German TL8135-0043, which take 24 hours or more to measure the effectiveness of VCI in film and paper.

However, for those in need of a faster solution for VCI quality control inspection, we present our patent-registered Rapid 3-Hour VIA testing method (R3-VIA), a quick and effective same-day VIA testing method for VCI film and paper.

The R3-VIA test maximizes the VIA of VCI film and paper within 3 hours at a temperature that maximizes rusting on metal specimen discs.

Testing Procedure at a Glance:

1. Three 1000 mL Erlenmeyer flasks with VCI testing materials and one 1000 mL Erlenmeyer flask without VCI testing materials are required.

2. Three of the Erlenmeyer flasks will contain two strips of 2.5 cm x 15 cm VCI test materials, one metal specimen disc. The fourth flask will only have a metal specimen disc without VCI testing materials.

3. Place the flasks in a climate chamber set at 50°C for one hour.

4. Equilibrate the flasks at 23°C +/- 2 room temperature for 50 minutes and add 10 mL of a 1:2 solution of glycerin and distilled water to each flask.

5. Place the flasks back in the climate chamber for 40 minutes to create unfavorable conditions for corrosion.

6. Assess the corrosion results on each metal specimen disc.

GreenVCI R&D Co., Ltd. looks forward to serving your company with green volatile corrosion inhibitor products and solutions.

The most widely accepted methods for testing VCI (vapor corrosion inhibitors) include the Salt Spray Test, Contact Corrosivity Climate Control Test, and Vapor Inhibiting Ability (VIA) tests from the US Department of Defense MIL-STD-3010 method 4031, NACE TM0208-2018, and German TL8135-0043, which take 24 hours or more to measure the effectiveness of VCI in film and paper.

However, for those in need of a faster solution for VCI quality control inspection, we present our patent-registered Rapid 3-Hour VIA testing method (R3-VIA), a quick and effective same-day VIA testing method for VCI film and paper.

The R3-VIA test maximizes the VIA of VCI film and paper within 3 hours at a temperature that maximizes rusting on metal specimen discs.

Testing Procedure at a Glance:

1. Three 1000 mL Erlenmeyer flasks with VCI testing materials and one 1000 mL Erlenmeyer flask without VCI testing materials are required.

2. Three of the Erlenmeyer flasks will contain two strips of 2.5 cm x 15 cm VCI test materials, one metal specimen disc. The fourth flask will only have a metal specimen disc without VCI testing materials.

3. Place the flasks in a climate chamber set at 50°C for one hour.

4. Equilibrate the flasks at 23°C +/- 2 room temperature for 50 minutes and add 10 mL of a 1:2 solution of glycerin and distilled water to each flask.

5. Place the flasks back in the climate chamber for 40 minutes to create unfavorable conditions for corrosion.

6. Assess the corrosion results on each metal specimen disc.

GreenVCI R&D Co., Ltd. looks forward to serving your company with green volatile corrosion inhibitor products and solutions.

EN

EN